FreeFlow

Paraffin, Scale & Corrosion control

Try It Out!

Revolutionize Your Operations with Cutting-Edge Scale, Paraffin, and Corrosion Control Technology

Designed for the vanguards of Oil & Gas, SAF, Geothermal, Mining, and CCUS industries.

FreeFlow Got You Covered

Paraffin congeal prevention

FreeFlow dewaxes the required areas in the shortest possible time with a tangible economic and environmental impact.

Scale Prevention

Scale formation is one of the major challenges faced by operators. FreeFlow prevents scale formation extending the life of pumps and tubular.

Corrosion prevention

FreeFlow prevents corrosion while extending the life of wellbores, pipelines, refineries and surface facilities.

Cutting-Edge Tech

Achieve peak production flow rates while eliminating or substantially reducing production interruptions.

The Benefits of Using FreeFlow

1. No Downtime

With FreeFlow technology, you can maintain production during the installation.

The FreeFlow unit is mounted at the surface without interruption to operations. On-site installation usually takes less than two hours.

2. Maintain Production

FreeFlow technology enables you to maintain maximum production rates and reduce production interruptions associated with scale and paraffin remediation.

With the fluctuating prices of crude oil and natural gas, lost production can be the single largest cost associated with scale and paraffin deposits.

3. Eco-Friendly

Ultra-green FreeFlow technology eliminates or substantially extends the periods between scheduled maintenance, cleanups, and disposal of hazardous wastes, such as normally occurring radioactive materials (NORMs) and spent acid.

4. Cost & Time Savings

Paraffin inhibitors, PPD’s, etc., will cost the industry $2-3 bill. per year by 2025. Paraffin inhibitors are commonly used to help mitigate or reduce the effects of wax deposition during petroleum extraction, refining, and transportation. However, these chemicals come at a high cost & usually are not very effective.

Protect What Matters 24/7

Groundbreaking Technology at Your Fingertips:

FreeFlow delivers relentless defense against paraffin crystallization, scale accumulation, and corrosion, safeguarding your wells, downhole equipment, and surface assets. Our technology extends the life of your valuable assets securing your investments and ensuring lasting returns.

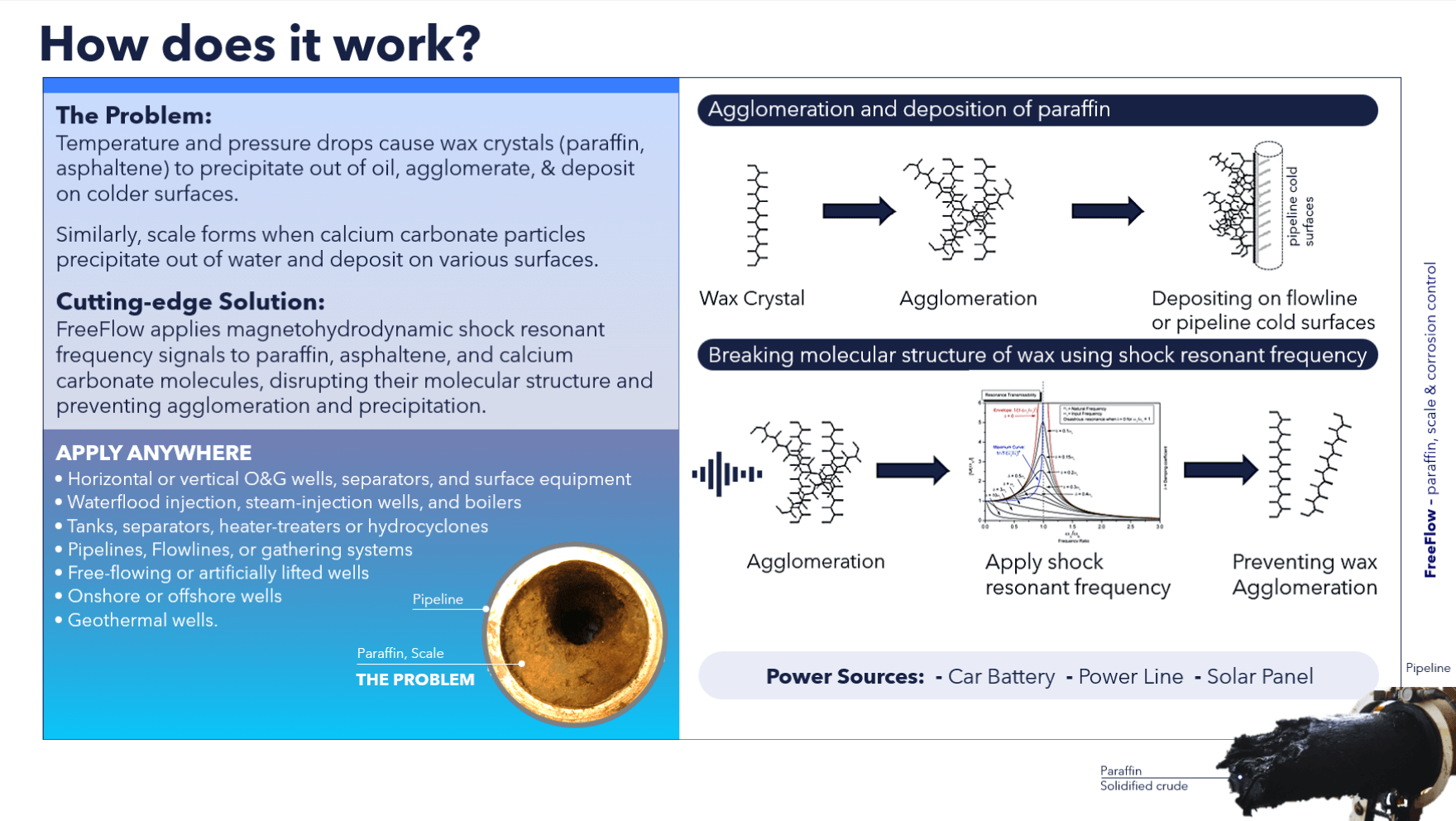

How It Works:

At the heart of FreeFlow lies our pioneering use of magnetohydrodynamic shock resonant frequency signals, designed to dismantle the molecular structure of scale-forming minerals and paraffin. This revolutionary approach prevents their precipitation, ensuring smooth, uninterrupted operations from the wellbore to surface facilities.

Wax & Scale Prevention

in 3 simple steps:

1. Data gathering

2. FreeFlow Manufacturing

3. Installation

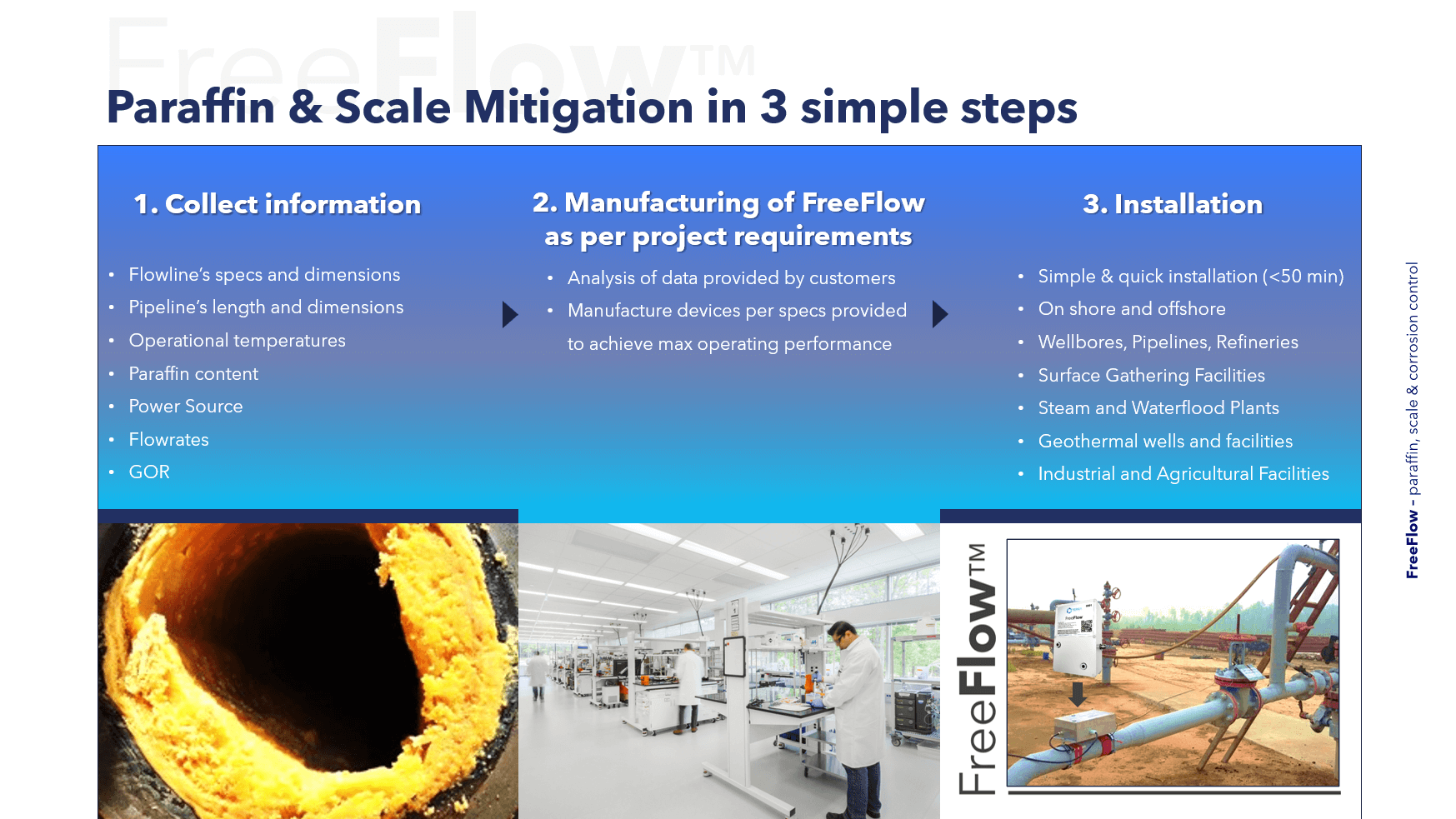

1. Data Gathering:

Our first step is a thorough exploration, gathering critical data about your systems, challenges, and goals. It’s the foundation upon which we tailor the FreeFlow solution, ensuring it’s perfectly aligned with your unique needs.

2. Precision Crafting:

In our state-of-the-art facilities, your unit is meticulously engineered with precision, embodying our commitment to quality and your operational success.

3. Seamless Integration:

The final step is where transformation takes place. Our expert team ensures a swift and seamless installation of your FreeFlow device, integrating it into your system without interrupting your production flow.

A Legacy of Success

Our technology isn’t just innovative – it’s proven. From the high-pressure wells of the Uinta Basin to the challenging climates of Kazakhstan and Russia, FreeFlow has proven its mettle. It’s more than a product; it’s a partner in your journey to operational excellence.

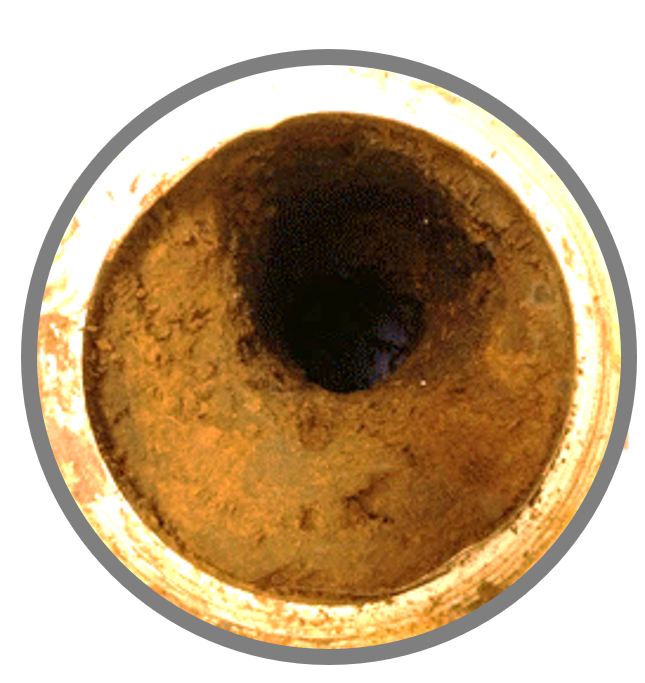

Problem: Paraffin solidification in a pipeline

FreeFlow devices were successfully installed on multiple pipelines and wellbores in Kazakhstan and Russia. Pipelines had to be continuously cleaned, and millions worth of PPD chemicals had to be pumped to prevent rapid solidification of paraffin and to reduce the pour point temperature.

After the installation of the free-flow devices, these issues were alleviated, substantially improving the economics, reducing environmental impact, and improving supply chain-related issues.

Problem: Severe scaling issues in HTHP gas well

An operator experienced frequent well shutdowns because of CaCO3 and barium sulfate scaling at 3,962 m, HTHP gas well. The operator spent $400,000 annually to keep the well producing, including weekly acid jobs, replacement of corroded tubing strings, & installation of expensive high-alloy equipment. Two month-long well workover cost $720,000 in lost production. Once the FreeFlow device was installed, it eliminated all scale-related maintenance. Well continues to produce without the need for scale inhibitors or acid jobs.

Problem: Scaling and ESP failures

A south Texas operator wanted to increase the production on an 8,000-ft gas well that was already using a conventional rod pump for artificial lift. When a new electric submersible pump (ESP) was installed, the well-scaled up in three days. A scale squeeze was applied, and a continuous scale-inhibitor injection was started. The well-run length was extended to 90 days. A FreeFlow unit was installed on the wellhead, and the well has continued to operate for more than seventeen months with no scale buildup on the ESP or the flowlines.